Versatility and reliability for demanding bakers

Offering equipment for industry and artisan bakery, Minipan has many bakery solutions to offer. The portfolio of applications includes a variety of bread snacks such as breadsticks, grissini, seeded flatbread, crackers, and regional snacks like taralli and rosquilletas. Specialty breads like baguettes and focaccia with high water content, artisan breads without using extruders, sandwich bread, rusk, hamburger buns, and various regional shapes of bread. The range also includes biscuits and cookies, including deposited, wire-cut, and hard biscuits, stuffed cookies and bars, biscotti, healthy bars, krumiri, muffins, ladyfingers, and sponge cakes. Additionally, there are gluten-free options available, including breads, pizza shells, ciabatta, focaccia, snacks, flatbreads, crackers, biscuits, cookies, sponge cakes, and muffins. The portfolio is complemented by tray handling automation equipment such as rack loaders and unloaders, de-panners, paternoster proofers, and customized conveyor systems.

High performances, sanitary design, terrific reliability. It doesn't matter whether you need to shape bread, bread snacks, cookies or gluten-free, you will find the best solutions on the market with the highest quality standard.

More information on minipan.com

Bread, pizza and pinsa

R_EVOLUTION Line

Great artisan bread needs time to develop an amazing texture and flavor and R_EVOLUTION Line is designed to assure to the dough all the time needed, with flexible and controlled retarding time and temperature.

The logical consequence of the time feature: patience. R_EVOLUTION Line does not stress the gluten network generation process with chemical nor technological short cuts. Minipan designed the solution with a large and slow belt to let the dough rest while developing.

The knead is handled with extreme care. Working with a hydration level up to 85% involves a high level of risk to damage the dough and jeopardize the final product, so care is a must. Minipan believes that, for this kind of recipes, extruders and volumetric dough breakers are too aggressive, so they designed a soft and slow sheet generation system that processes the dough very lightly.

Advantages:

+ Traditional sheet generation (no extruders, no dividers)

+ High hydration dough easily processed

+ Small batch loading

+ Long-time resting

GRISSINI AND BREAD SNACKS MACHINE WITH MINIPAN EXCLUSIVE SCRAP FREE TECHNOLOGY

GRESEX 660

The essence of flexibility. An amazing range of shapes: grissini of every shape and diameters, bread loaves, but also flat breads of thickness below 1mm. Everything completed by an integrated topping device for sesame or poppy seeds, with automatic recovery of the excess.

GRESEX is a complete, reliable and modern solution, to guarantee a long lasting investment: many machines in one, to afford the always more moody market.

Furthermore, thanks to Minipan exclusive SCRAP-FREE technology, there is no lateral waste. No waste, no unjustified costs of the process, more savings, more revenues.

GRESEX. So flexible that will never pass fashionable.

Advantages:

+ High Versatility

+ Scrap Free Technology, no waste, more revenues

MINIPAN SOLUTION FOR BREADSTICKS, GRISSINI AND THIN BREAD SNACKS

GRISS 660

Versatility to serve creativity.

GRISS 660 is a flexible breadsticks machine with tray up system, recommended for medium size production demand. Thanks to a complete choice of customizable options, grissini shapes and dimensions are not a limit anymore. GRISS 660 guarantees great performances with low labor demand. Suitable for baking pans from 400 to 660 mm of useful width, this machine is the essence of Minipan’s spirit: automation open to improvements.

Advantages:

+ High versatility

+ High customization options

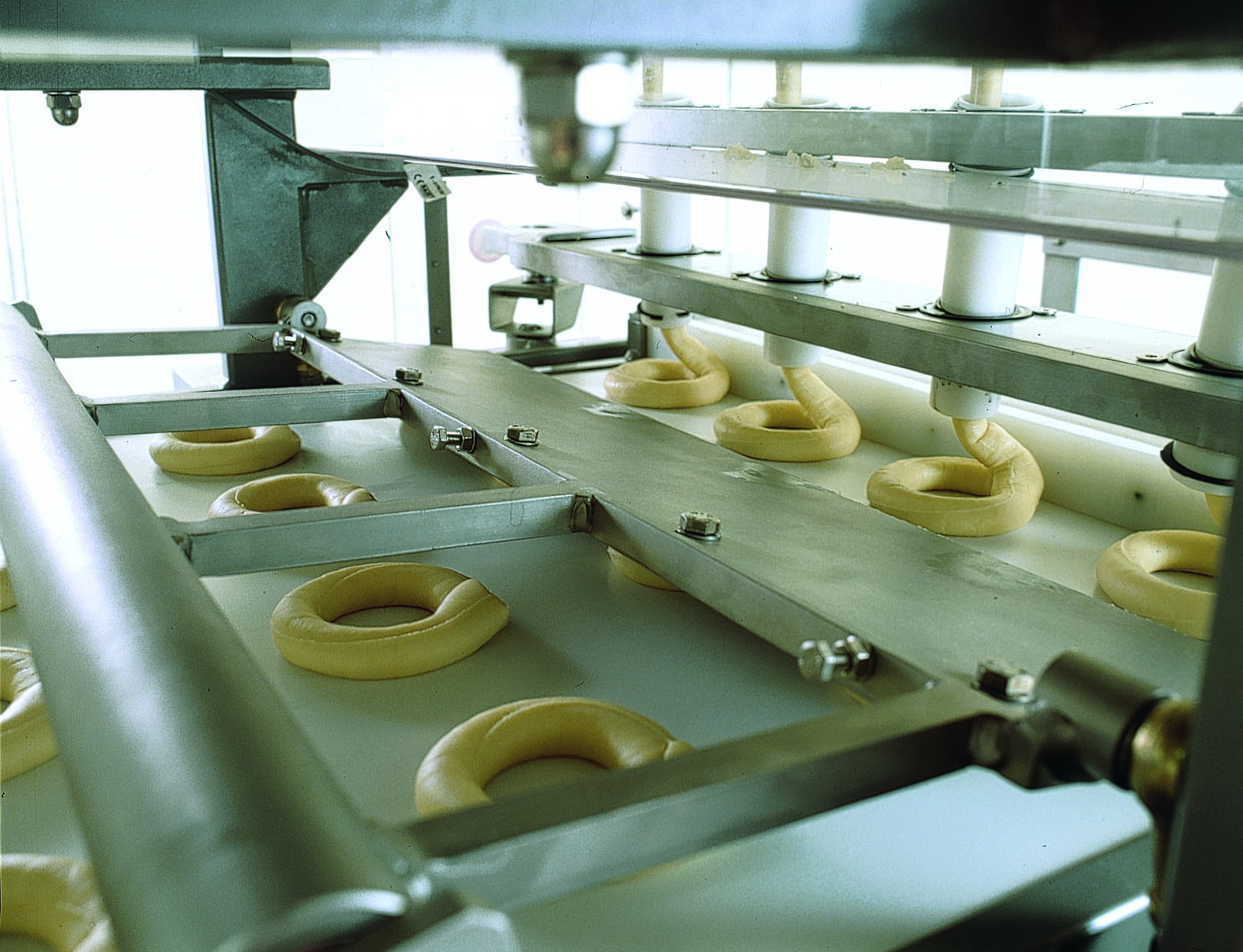

THE ENTRY LEVEL SHAPING MACHINE FOR TARALLI AND O-SHAPE BREAD SNACKS

O-MATIC 600

Flexible in production, O-MATIC 600 is the entry level of Minipan’s automatic forming machines for taralli and grissini. Due to its improved optional fittings, shape and dimensions of the product are virtually unlimited. Our research on the simplicity of use makes O-MATIC 600 the perfect tool for the most creative bakers. Suitable for trays from 400 to 600 mm of useful width, O-MATIC 600 is the essence of Minipan’s spirit: automation open to improvements. O-MATIC 600, with its complete PLC control, is delivered ready to be integrated with tunnel boilers, dough sheeting/feeding lines, baking pans motorized conveying and automating rack loading machines.

Advantages:

+ Versatility

+ Highly customizable

THE UNIQUE MINIPAN SHEET GENERATOR WITH PUNCH & FOLD TECHNOLOGY

RAFFINATORE

Thanks to its punch & fold technology, RAFFINATORE is the only machine able to improve chunky dough for bakery products and is particularly efficient in the lamination of flatbreads, crackers, grissini and bread snacks. Employing our unique automatic cross lamination feature, RAFFINATORE is able to improve the gluten protein network and to provide a perfect distribution of the carbon dioxide bubbles, yielding a very fine crumb. As a result, the structure in products like tin bread and sandwich loaves is supported by a completely homogeneous development, as well as perfect crumb stratification for products like galletas de agua, hallulla and piadina.

Advantages:

+ Improve the gluten protein network

+ Provide a perfect distribution of the carbon dioxide bubbles

AUTOMATIC TRAY UP LINE FOR BREAD SLICERS

Crostini and croutons tray up line

PLC controlled crostini rephasing and tray up line is connectable to automatic bread slicers. The rephasing system is able to provide a unique performance in reordering the rough disks of bread coming from the bread slicing machine. The vibrating conveyors flatten the sliced disks and the rephasing device is helpful to fill the useful width of the conveyor belt that drives the product to the baking pans. A set of sensors controls that the belt is completely filled on the width and the length desired in order to forward the product with a consistent distribution. The baking pans are then forwarded to the toasting stage.

Advantages:

+ Less manual work

+ More saving